|

Why are instruments finished? All musical instruments are finished in some way. They all gain and lose moisture according to the prevailing climatic conditions, and this process puts great strain on the wood of which the instrument is made. If it can't expand or contract with changes in moisture content, it splits. Unfortunately, it is not possible to make instruments that can support the stresses imposed by stringing them up, and move with changes in humidity. The only answer is to limit the effects of changes in humidity. They are finished because it is the only real way to minimise the effects of climate on the instrument, and to protect the instrument from damage whilst it is being played. Finished wood 'moves' much much less than unfinished, because it is protected from most of the moisture gain and loss. |

|||

| Typical Finish Damage | |||

|

When an instrument arrives, the first impression is

created by the finish. Many look 'tired', with the finish

scratched and lacking in much shine.

The lacquer finish to the left has suffered from discolouration and crazing over the years, and looked terrible. |

|

When scraped back to the wood, it is possible to see what the original colour of the instrument was. I know of no way to recuperate a finish so discoloured and crazed, so I generally remove it and re-finish the instrument. |

|

These two pictures display different but common

problems.

Left, the finish has been so worn as to be substantially not there, with no lustre, no depth, and offering almost no protection to the wood. |

|

On the other, the finish is still present, but so badly scraped and scratched it would be extremely difficult and time-consuming to 'touch-up', and leave an acceptably pleasing result. Again a re-finish seems the only real option. |

|

These pictures of backs illustrate more typical

scenarios.

Left has reasonable varnish over most of the back, but significant damage in the lower part, where the instrument would rub against the body of the player. It always looks less than satisfactory trying to touch this up. |

|

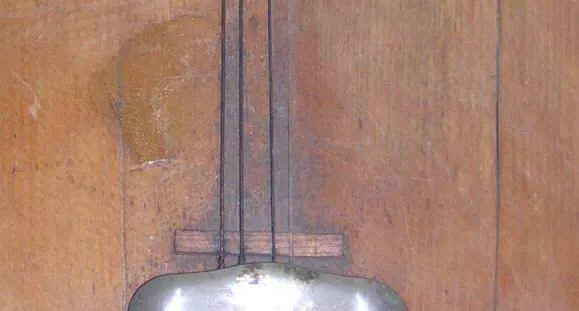

Left again, the varnish is substantially worn away, and needs to be scraped where the exposed wood is very dirty. |

|

Here the damage is extensive, and the surface is badly pitted. It must be taken back to wood and sanded smooth again, before new varnish can be applied. |

|

Here the varnish is largely intact, but I have never succeeded in

making any covering varnish look good on such a surface.

Perhaps it is the thin nature of the Tru-oil that I use?!

|

| What can I do with a damaged finish? | |||

|

Firstly, it is necessary to say that instrument finishing is a

complex area, and finish repair, given the variety of dyes and

finishes possible, is even more complex. Often the simplest option

is to re-stain and finish from scratch. Though should you wish to

repair, continue reading......

In order to know what can be done, it is useful to have some background knowledge. It is then possible to decide whether you wish to a) clean up the varnish, b) repair the existing finish, or c) completely re-finish the instrument. Many old instruments will be stained, and using the wrong sorts of varnish for the stain, or touching up old varnish with something incompatible, is likely to cause you more problems than you are solving. Some basic knowledge will help to avoid these problems. |

|||

| (a must to read before you start) * Health Hazards * (a must to read before you start) | |||

| Cleaning the Finish | Types of Finish | Wood Preparation | Pore Filling |

| Repairing Finishes | Stain | French Polishing | Oil-Varnishing |

| Water-based Varnish | Buffing | Finishing with Tru-oil varnish | KTM-9 water-based lacquer |

|

Further Reading: There are many books on finishing, and a

lot of good advice on the net and on the luthier supplier sites,

but I have found the following 2 books very informative and

detailed, particularly on the chemical background, and exposing

long-held myths...

1. 'Hand-Applied Finishes' by Jeff Jewitt, published by Taunton Press and 2. 'Understanding Wood Finishing' by Bob Flexner, published by Readers Digest. |

|||