|

Once the pieces were cut, planed and sanded to some extent, I approached the problem of assembling them. When building mandolins, I use a form to hold the pieces together to achieve the correct orientation, at least to start with. In the plans there was nothing about this type of approach, so I was forced to fall back on clamps and elastic largely. |

||

|

The top illustrates the problem with the whole harp.... a simple fairly small piece, but every side is angled, no corner is a right angle. Also, the top must be cut into as perfect a circle as possible. | |

|

Here is the harp base, which exhibits the same problems. Without the angle guide it would have been impossible to cut with any accuracy. |

|

|

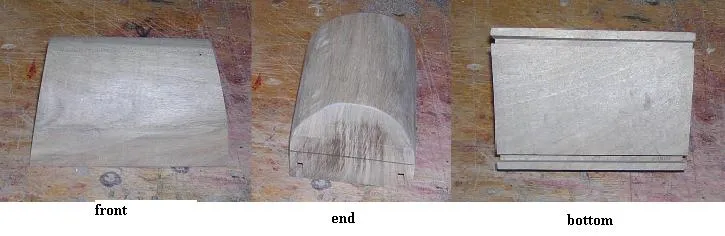

In the plan, part of the frame is secured with

screws, through the bottom, as well as glue. With the help of

clamps and elastic, it was possible to hold everything in position

while the glue set, not easy as no angles are square, and the

clamps slip easily. Here is the box frame assembled.... top bottom

and 2 sides.

In the second harp, I decided to omit the 4 screws through the bottom. |

|

|

As the delicately angled joins were not altogether perfect, I

decided that the whole structure would benefit from a little

interior re-enforcement. I glued a small strip into each corner.

|

|

|

One of the most awkward parts of the construction,

was the fitting of the arm on top of the head. A

concave section at the end of the arm needed to fit over

the convex top of the head. Both had been carefully cut by

hand, but even so, the match was not altogether what I would have

wished.

After several abortive efforts to sand them 'together', I finally hit upon the idea of curved sanders. I found a piece of drain pipe that was exactly the radius that I needed. Helpfully, at the end of a section of drain, a pipe widens, so the next section can fit into it. I uses the wider end to fit the sandpaper inside, and the narrower end for outer paper. In this way, in theory, I could sand 2 matching curves. |

|

|

Trial fitting the front............ It slides from the bottom, up

into the slots routed in each side. As the slots are only 3-4mm

deep, I did not want to over-cut it, so fitting took several

attempts, until it fit snugly.

Once cut to fit, the front is glued on all sides and nailed to the base at the bottom, (in the second harp I screwed in down) and a strip fitted over the top to finish it off. |

|

|

The back was the same, only slightly easier to manipulate on account of the holes. Once ready to glue in place finally, both front and back are pinned in place at the bottom. |

|

|

Once assembled, it remained only to stain the wood. I used water

based dyes, that wouldn't react with the Tru-oil finish I intended

to use. I did not stain the back or soundboard.

Once stained and assembled, it looked like a harp at last. The foot of the pillar is held in place by a screw from underneath, but the top arm, is held solely on the box top by string pressure. Thats the next bit...........

|

|

|

A particular problem, was the fitting of the foot. The photos show

that the arm is mounted at one side of the head to allow the

strings to descend centrally. The foot however is located in the

centre.

This means that the foot must be angled laterally, and front to back, so that it meets the base level. When the arm is not stable, as it only rests on the head by string pressure, this is a particularly difficult fit to make accurately, and required several 'slicings' off the foot until it was correct. |

|