| Re-veneering the head (For neck veneer, see the restoration parts page.) | |||

|

The old Italian bowl-backs, tend to have necks and heads made from a cheaper wood like maple, and be veneered in the more expensive rosewood. Not only is the head a convoluted shape, the veneer thus glued on in small pieces, many narrow or curved, but it is also pierced by tuners and their attendant screws. As a result, damage to this veneer is frequent. |

It is difficult to match the colour pattern and thickness of a veneer, evidenced by an old repair. Often it is only feasible to re-veneer the section. This one has been glued and drilled, but not as yet been 'finished'. | ||

|

1. In this example, the head has split completely, and though it has been successfully re-glued, the damage to the veneer is all too visibly ugly. |  |

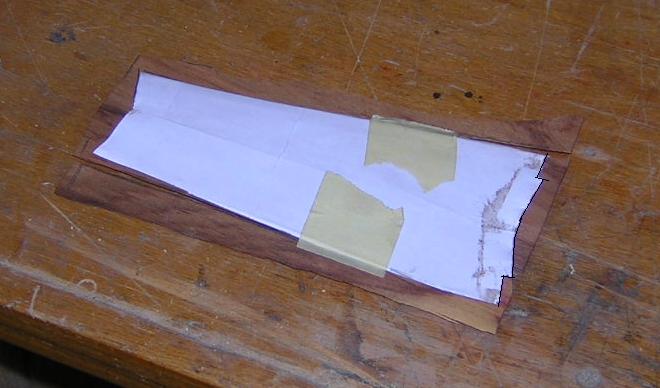

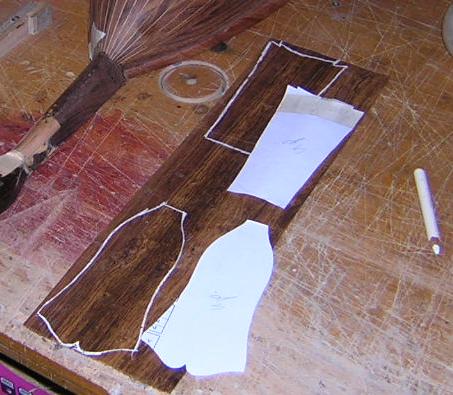

2. After removal of the furniture, the head is sanded smooth in readiness for a new veneer, cut a little large from a larger sheet. |

|

3. The new veneer is then glued in place, and held under pressure by a clamp whilst the glue dries. Care must be taken here not to let the veneer slip as pressure is applied. |  |

4. After the glue has set, the new veneer is then trimmed down to size, and the edges very carefully sanded round and smooth in readiness for the finish. |