|

Shelf Bridge |

|

| Making any shelf bridge, whatever the exact design, follows more or less the same routine. If you have the mandolin to hand, fit the foot first, if not, leave a couple of mm for fitting later. Here I have assumed we do NOT have the mandolin to hand..... | |

|

|

|

Most classical mandolin bridges are 120mm in length,

though some can be as long as 135mm.

Starting with a large block of ebony or rosewood, either fit the foot on the large block, or cut bridge blank 120mm about 15mm tall. With the plane, make sure the top is flat and level. If you have fitted the foot, work out the height you will need, and cut off the fitted section at that height. |

Put the block in a vice, and mark the half way point

(60mm) Either side of this, mark the ends of the shelf to be cut,

25mm each side, making sure the cut mark angles back towards the

centre, so that later it will hold the saddle well. Then cut each

of the two diagonal lines with a thin saw blade.

The shelf will then be 50mm long, which is sufficient for a typical string spread on a Neapolitan of around 38mm. |

|

|

|

|

Cut out the shelf carefully with a small chisel.

Take great care at the ends of the shelf, you don't want to damage the diagonal end. |

I tend to favour a 5-6mm chisel which I use on the flat, (as in the photo) not upright, as I find I can control it better. |

|

|

|

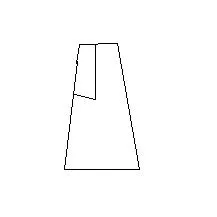

| When the slot is finished, you need to make sure is is clean right into the corners, I use a craft knife. Also, and bottom of the shelf should be angled inwards, to help retain the saddle. | It should look like this when the shelf is cut. Here I have marked out the edges for better visibility. |

|

|

|

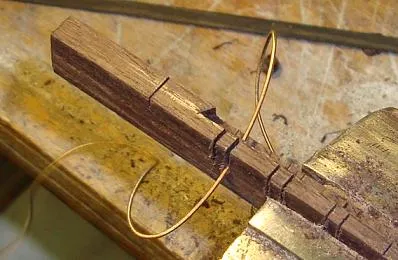

| It is at this point, once the shelf has successfully been cut, that I add any taper required, by clamping an passing an angled plane over each side. Care must be taken with the shelf side. | Next I use the graduated saws to cut the string slots. Gaps are generally 2 - 2.5mm between slots. I cut the left slot first, and then press my thumb onto the string splitter whilst cutting the right hand slot. This helps to stop a careless saw movement breaking the small section. |

|

|

|

| Next, measure 25mm from each end, and make a saw cut there about 2mm deep. This will be the wing. | The wing needs to be less substantial than the body of the bridge, so as not to catch the hand, so it is pared down, either with a chisel (20mm used flat) or a saw. |

|

|

|

|

The bridge is then turned sideways in the vice, and

both wings are tapered down, from the centre working outwards, but

not quite to points.... this will be done when sanding later.

Again I use a 20mm chisel flat to pare away from each side. |

Cut a 2mm deep slot in each side, 25mm from the end, as with the top. |

|

|

|

| Approaching this time from the end of the bridge, pare away a little wood in towards the new slot. Take care at the end not to cut into the body of the bridge. Again I do this with a flat chisel. | You now have your rough bridge made. |

|

|

|

| To open up the slots for the bottom string I use an off cut of the same gauge. The graduated saw stops at 0.025", which is not wide enough. | The next step is the polishing, for which I clamp it into the vice, using 80, 120, 240, 320, 600 800 and 1000 grade sandpaper. Do each side and then the top.... take care with the fragile wings. |

|

|

|

| Just in from both wings, cut one or two slots about 1mm deep. These will be purely for decoration. | Turning the bridge on its side in the vice, continue to cut the slots down each side. |