| The

Task

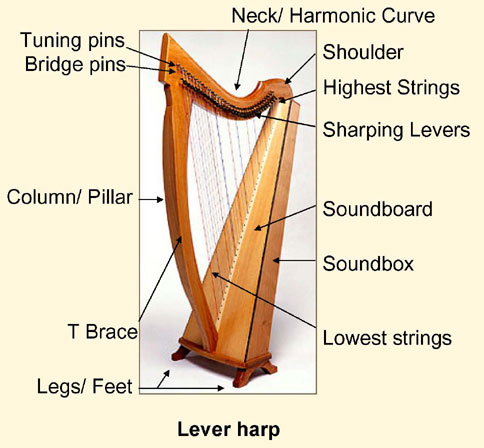

Recently I was asked to build a harp by a member of the traditional Irish group in which I play, and when I agreed, it became apparent that another member of the group had also always wished to acquire a harp. So I committed myself to building two. Both finished. As with the mandolins, I took photos during the construction, and this section is a record of that learning experience! Some of the problems I had with the first, I managed to avoid with the second. I chose to build the harp from the plans only, sourcing the wood locally. For what it would have cost to buy the wood WITH the plans and ship it, I could have bought a finished harp, so I ordered only the plans, strings and hardware. Also, because I only intended to make 2, I did not want to buy a lot of specialised equipment that perhaps would not be used there-after. (Not to mention the expense and lack of space!!) So I have attempted to build these with only the hand tools found in a typical workshop, a router, and a bandsaw for the heavier cutting.Problems and solutions are dealt with in the following sections. |

||

| Sides |

|

Assembly |

| Pillar & Arm | Finishing | |

| Back | Stringing | |

| Sound board | Gallery | |

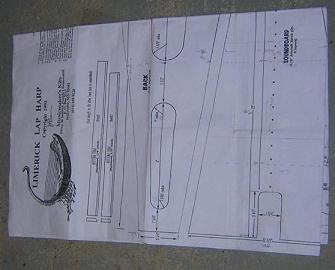

| The first problem was to find plans for a harp, having never made one before. I decided to tackle a lap harp, as being of a realistic size to start on, whilst still giving more than two full octaves range. |  |

Eventually I found a set of plans at 'Musicmaker's Kits' in the States, which had the added advantage that they also sold the hardware for the harps and the strings as well. It was a good place to start, but the plans have not been without their problems?!

|

|

The harps started

off like this, several rough-cut planks of maple and walnut, from the

local saw mill, about 30mm thick. I decided also, to use a couple of

old maple neck blocks, which were a bit thicker, for the arm and pillar

of the first. I also needed guitar topwood for the sound boards and

backwood (maple) for the backs.

With all the pieces roughly finished apart from the soundboard and back, it looked like this. |

|